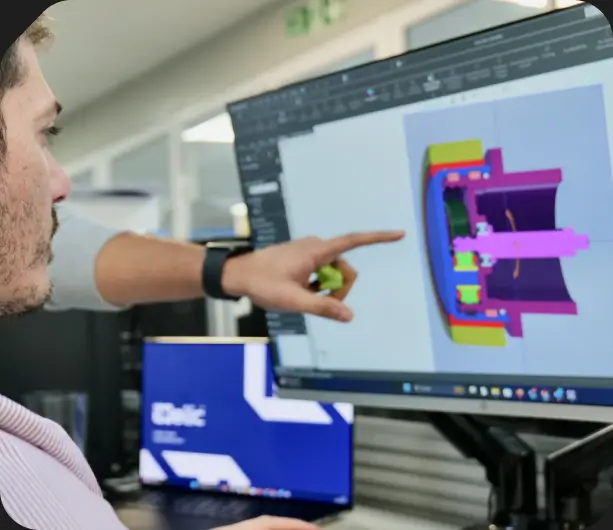

Fully parametric motor design template

Fully parametric motor design template

This capability involves utilizing a sophisticated template for motor design that offers a wide range of parameters and options. Engineers can adjust variables such as dimensions, materials, and configurations to customize the motor design to meet specific requirements efficiently. The template provides flexibility and streamlines the design process, enabling rapid iterations and optimizations.

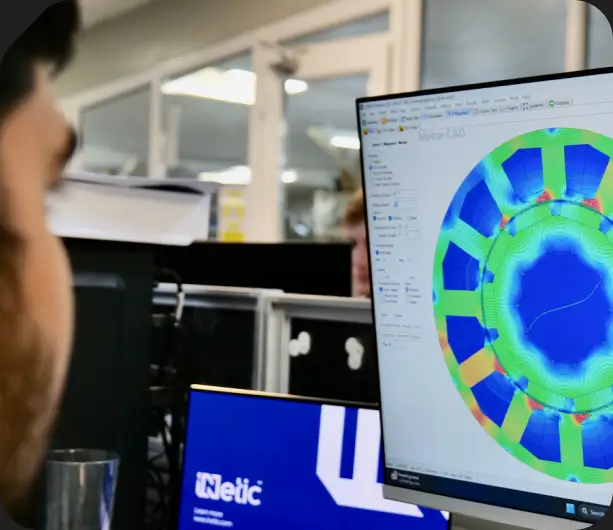

Finite Element EMAGE Simulation

Finite Element EMAGE Simulation

This capability employs advanced Finite Element Analysis (FEA) techniques specifically tailored for electromagnetic analysis (EMAGE) of motors. Through detailed simulations, engineers gain insights into the electromagnetic performance and behavior of the motor. This includes analyzing factors such as magnetic flux distribution, eddy current losses, and electromagnetic forces, allowing for optimization of motor design and performance.

Loss Reduction and Driving Cycle optimization

Loss Reduction and Driving Cycle optimization

With this capability, engineers focus on minimizing energy losses within the motor and optimizing its performance across various driving cycles. Strategies may include optimizing motor design to reduce friction and eddy current losses, improving control algorithms to enhance efficiency, and adapting motor operation to specific driving conditions. The goal is to maximize energy efficiency and extend the motor’s operational range.

Cost model for DMF

Cost model for DMF

This capability involves developing a comprehensive cost model that incorporates Design for Manufacturing (DFM) principles. By considering factors such as material costs, manufacturing processes, and assembly complexity, engineers can assess the cost-effectiveness of different motor designs. The cost model enables informed decision-making throughout the design process, helping to achieve efficient and economical motor production.

Short circuit analysis or demagnetization

Short circuit analysis or demagnetization

Engineers conduct thorough analysis of short circuit scenarios and demagnetization effects to enhance the reliability and durability of motors. This includes simulating the impact of short circuits on motor performance and designing protective measures to mitigate risks. Additionally, demagnetization analysis helps ensure that magnets maintain their magnetic properties over the motor’s lifespan, preventing performance degradation

Thermal simulation

Thermal simulation

This capability involves using sophisticated thermal simulation tools to evaluate and manage the temperature profiles of motors. Engineers simulate heat generation, conduction, and dissipation within the motor components to ensure optimal operating conditions. By preventing overheating, thermal simulation helps maintain motor performance, reliability, and longevity.

Torque ripple

Torque ripple

Addressing torque ripple involves employing advanced design techniques and optimization algorithms to minimize fluctuations in torque output during motor operation. Engineers analyze factors such as magnetic field distribution, rotor dynamics, and control strategies to mitigate torque ripple. This enhances motor smoothness, reduces vibration, and improves overall efficiency, particularly in applications requiring precise torque control.

Mechanical strength and fatigue

Mechanical strength and fatigue

Engineers assess the mechanical strength and fatigue resistance of motor components to ensure their long-term reliability and performance under various operating conditions. This involves analyzing stresses, strains, and fatigue life using methods such as finite element analysis (FEA) and fatigue testing. By identifying potential failure points and designing components to withstand mechanical loads, engineers enhance motor durability and longevity.

Tolerance Analysis

Tolerance Analysis

This capability involves performing detailed tolerance analysis to ensure manufacturing precision and consistency in motor production. Engineers analyze the cumulative effects of dimensional variations and assembly tolerances on motor performance. By optimizing tolerances and clearances, engineers minimize the risk of manufacturing defects and ensure that motors meet design specifications reliably.

High fidelity map generation

High fidelity map generation

This capability focuses on generating high-fidelity performance maps that characterize motor behavior under different operating conditions. Engineers use comprehensive testing and simulation techniques to capture data on motor performance parameters such as torque, speed, efficiency, and power consumption. These maps serve as valuable tools for system integration, control algorithm development, and performance optimization

Motor model (simultaneous engineering)

Motor model (simultaneous engineering)

With this capability, engineers develop a comprehensive motor model that integrates various engineering disciplines simultaneously. This includes electrical, mechanical, thermal, and control aspects of motor design and operation. By considering multiple factors concurrently, engineers optimize motor performance, efficiency, and reliability while streamlining the design process and reducing time-to-market.