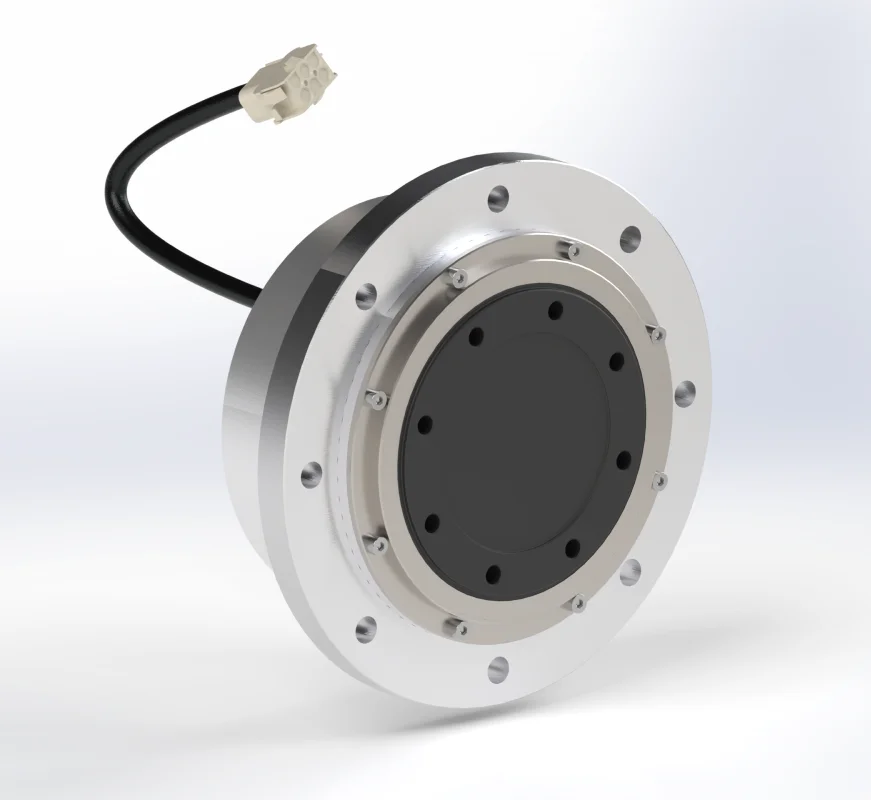

The race to create viable, functional humanoid robots is pushing engineering to its absolute limits. From bipedal locomotion to fine-motor hand manipulation, every joint – every actuator – presents an extreme challenge. The core problem? These actuators must deliver immense torque and precise control in a package that is simultaneously lightweight and incredibly efficient to maximize battery life.

This is where the standard “catalogue motor” approach fails.

Off-the-shelf motors are products of compromise, designed to serve the broadest possible market. They are rarely, if ever, optimized for the unique, high-performance-density demands of a robotic joint. Engineers who try to design around a standard motor are forced to accept compromises in weight, size, or efficiency, which cascade into larger batteries, heavier limbs, and poorer overall performance.

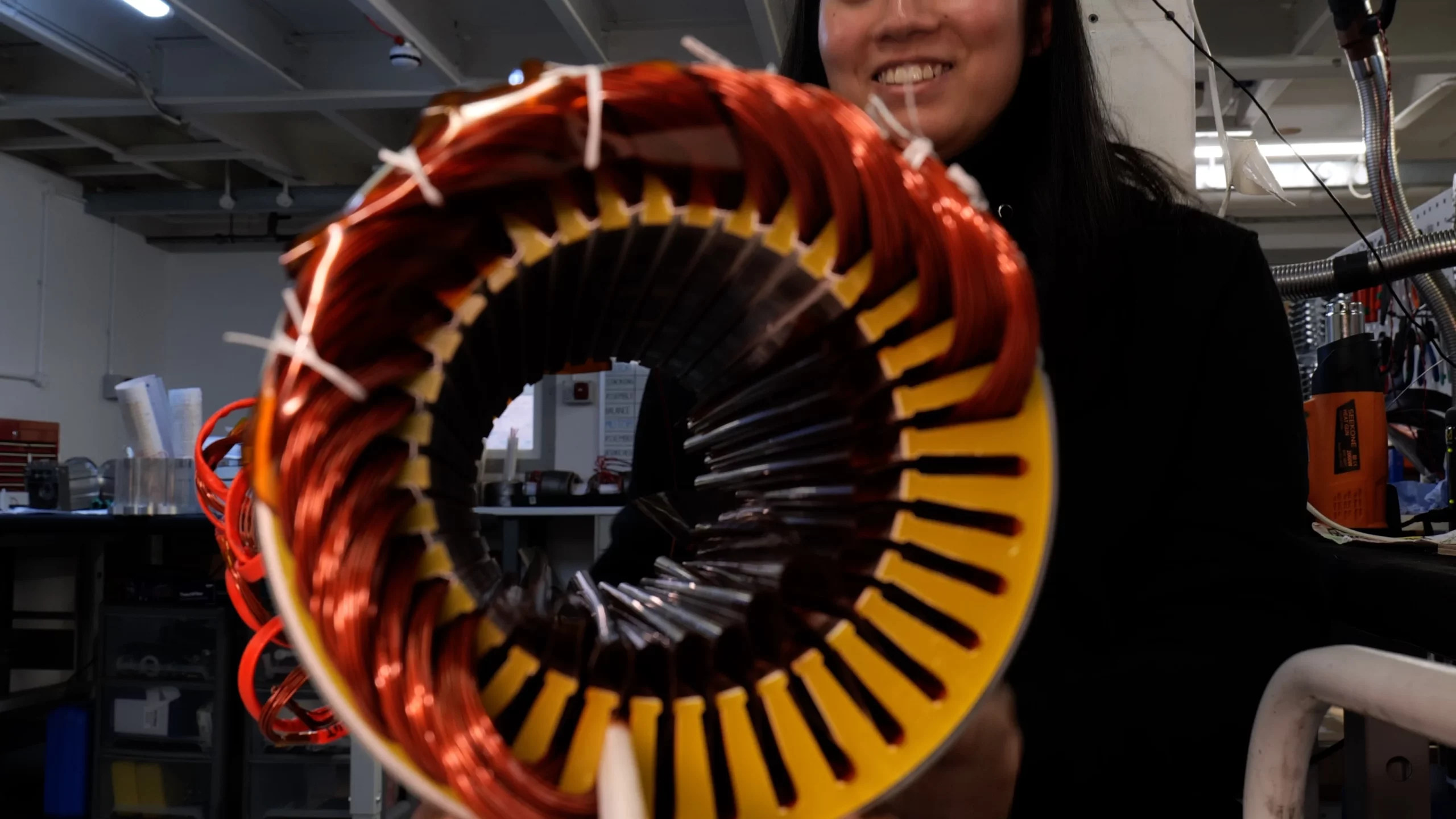

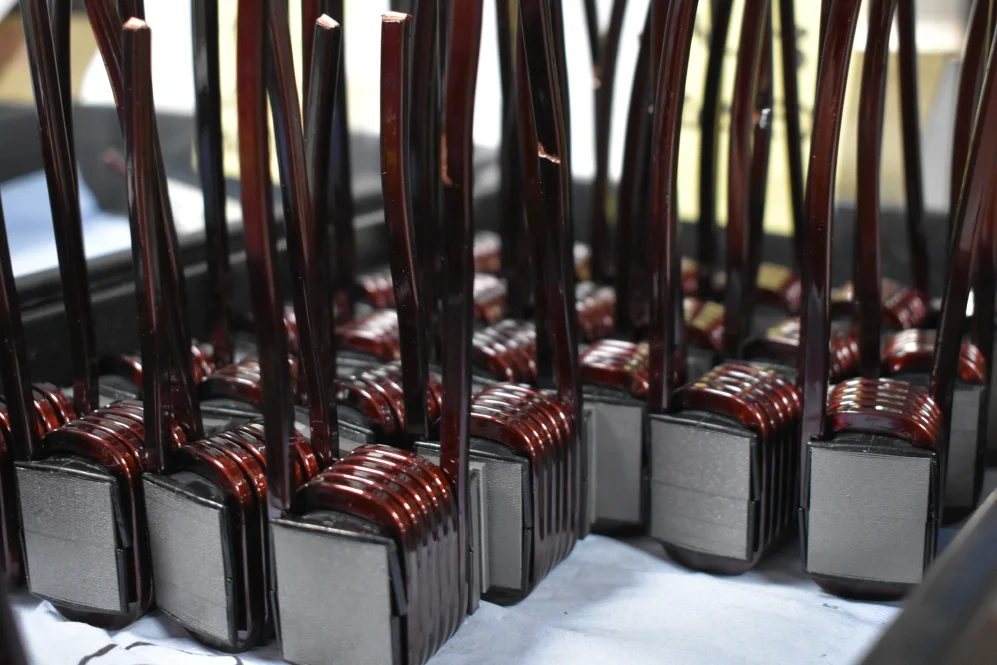

At iNetic, we believe this approach is fundamentally backward. Instead of forcing your design to fit a motor, we design the motor’s core “personality” to fit exact requirements for the arm, finger or leg actuator.