Integrated Robotic Joint Actuators & Their Applications

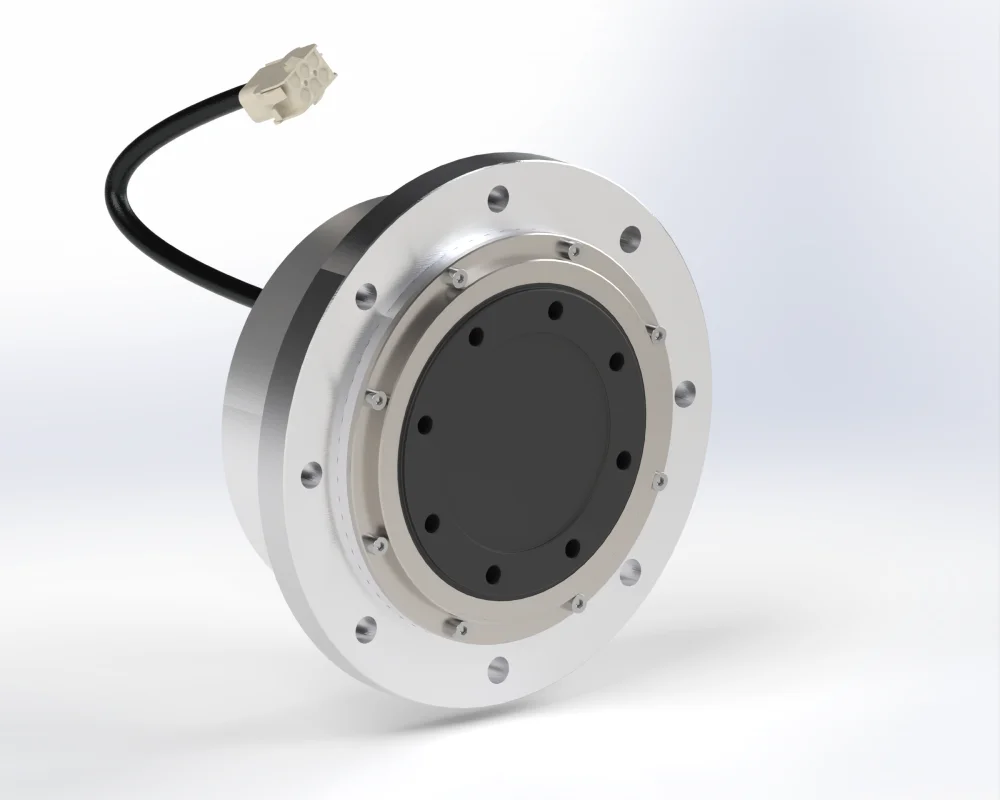

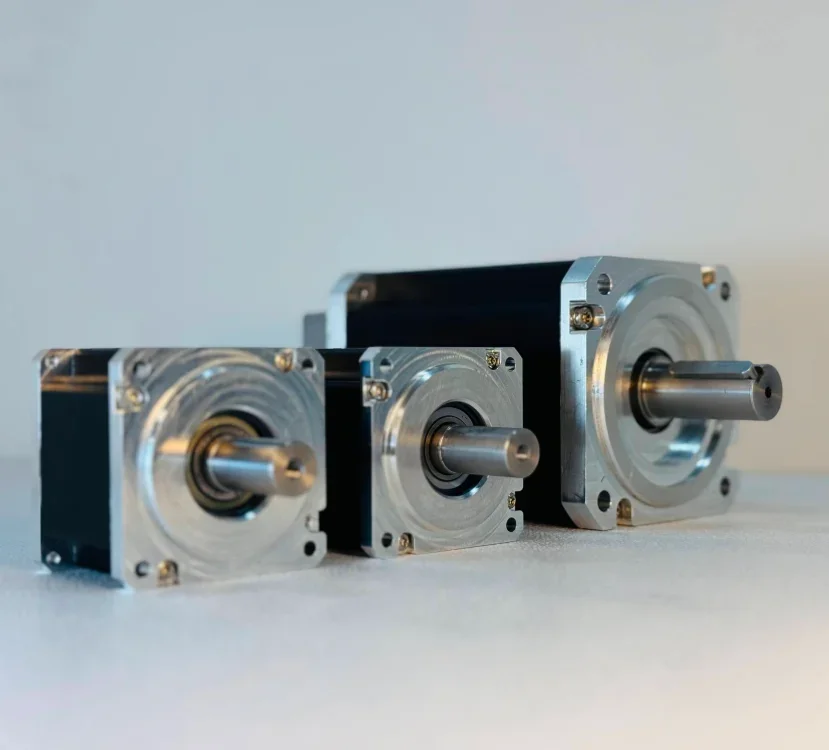

A robotic actuator is the complete motion unit, converting electrical energy into movement. Our integrated robotic joint motors combine the motor, gear system, encoder, and controller into one compact, efficient unit. This all-in-one design provides smoother motion, simplifies installation, and ensures perfect component synergy for superior motion control.

The iCO, iNX, and iND motor series are built for performance and reliability, powering modular robotics, autonomous systems, and industrial robot joint applications worldwide.

See our iND Series