In the world of high-performance robotics, automation, and advanced machinery, power and precision are paramount. But as our systems become more powerful, complex, and collaborative, another “P” becomes the most important of all: Protection.

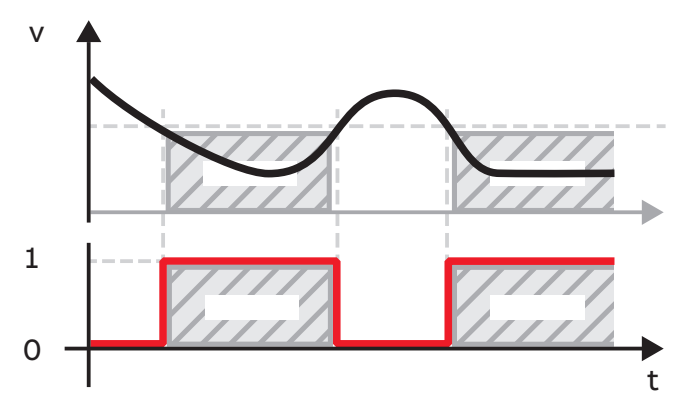

Functional safety isn’t just about painting a guard rail yellow or adding an E-Stop button. It’s about intelligent, active systems that constantly monitor a machine’s state to prevent harm to people and equipment. These functions are built directly into modern motor drives-the “brains” that power advanced motors like ours.

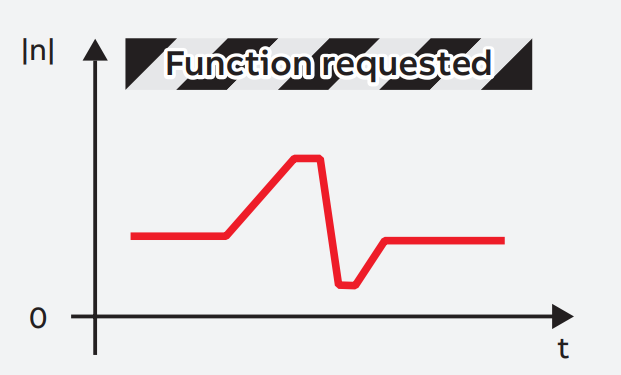

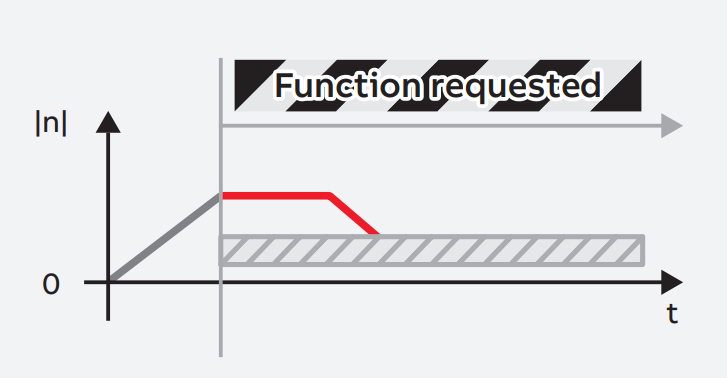

Understanding this safety alphabet is critical for any engineer designing a modern, safety-critical system. Let’s break down the most common safety functions you’ll encounter.